The Role of Industrial Motherboards in Automation Systems

Understanding Industrial Motherboards

Industrial motherboards are specialized computer motherboards designed for specific applications in sectors such as manufacturing, robotics, and embedded systems. Unlike standard motherboards used in personal computers, these are engineered to meet the rigorous demands of industrial environments. They have robust designs that can endure extreme temperatures, dust, vibration, and humidity, making them suitable for harsh operational contexts. This unique capability allows industrial computers, such as fanless industrial mini PCs and other industrial PCs, to perform reliably and efficiently in various settings, ultimately ensuring seamless operations in critical infrastructure.

The fundamental differences between industrial and standard motherboards lie in their durability and feature sets. Industrial motherboards boast a design focused on longevity and resistance to environmental stressors. For instance, they often include advanced cooling systems and protective coatings to preserve component integrity. Additionally, they are equipped with features to support a broader range of operating environments — such as extended temperature and voltage ranges. On the other hand, standard motherboards are optimized for typical consumer applications, prioritizing affordability and commonly used functionalities. Businesses needing long-term, reliable systems will benefit from choosing industrial motherboards over conventional options, owing to their enhanced capacity to handle industrial workload demands.

The Importance of Industrial Motherboards in Automation Systems

Industrial motherboards play a crucial role in automation systems, significantly impacting efficiency and productivity in industrial applications. These motherboards are integrated into systems that control manufacturing processes, robotics, and other automated machinery, enabling seamless operation and coordination. This integration is essential for facilities aiming to streamline operations and reduce manual intervention, ultimately leading to increased throughput and accuracy.

Durability and reliability are paramount in industrial motherboards, allowing them to withstand extreme environmental conditions. Unlike consumer-grade motherboards, industrial versions are designed to endure high temperatures, vibrations, and extended operational hours without compromising performance. These boards often comply with industry standards like MIL-STD-810, which ensures that they can handle the rigorous demands of industrial environments. By incorporating state-of-the-art materials and robust engineering, industrial motherboards maintain consistent performance under stress, providing long-lasting solutions for critical operational settings.

Types of Industrial Motherboards for Automation

The Mini ITX and Micro ATX form factors play a crucial role in compact automation solutions. Mini ITX motherboards, measuring a compact 17cm x 17cm, are lauded for their space-saving design while still offering the functionalities found in larger boards. These boards are ideally used in kiosks, media centers, and point-of-sale terminals where space and power efficiency are critical. Micro ATX motherboards, although slightly larger, offer substantial processing power and are often used in environments where cost and space efficiency meet performance needs.

Pico ITX and Single Board Computers (SBCs) are also significant in the realm of automation, particularly for embedded systems. The Pico ITX motherboard is incredibly small but powerful, making it perfect for applications like thin client computers and media streaming devices. SBCs integrate all components onto a single board, which not only reduces size but also enhances system reliability and ease of installation. These options are immensely beneficial in industrial settings where space constraints are prevalent, and deploying multiple systems is required.

Benefits of Using Industrial Motherboards

Industrial motherboards offer significant longevity and support, making them ideal for long-term investments. These motherboards boast extended product lifecycles, meaning users can expect a stable operation for many years without the constant need for replacements—a critical factor in industrial environments where consistency is key. Updates and replacements are more accessible than with regular consumer hardware, which ensures that technology remains relevant and effective over time. This is vital for industries that rely on seamless operation and cannot afford frequent downtimes or disruptions in their production lines.

Additionally, the performance optimization of industrial motherboards in harsh environments is invaluable. These motherboards are engineered to perform reliably under extreme conditions, such as high temperatures, dust, and humidity, which are commonly found in industrial settings. For example, fanless industrial mini PCs incorporate robust temperature and humidity thresholds to withstand these rigorous conditions without compromising performance. This reliability under adverse conditions is essential in industries such as manufacturing and automation, where equipment must consistently operate without error. The ability to maintain high-functionality standards under such severe conditions is a significant advantage of industrial PCs and server motherboards over their more fragile counterparts.

Product Showcase: Top Industrial Motherboards

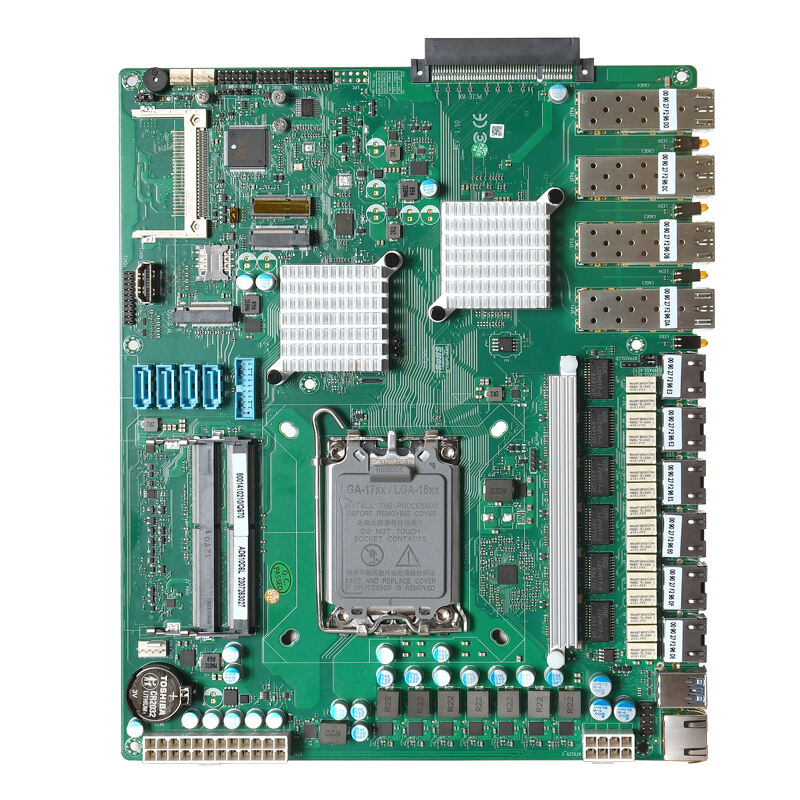

The Piesia 6Lan 4*10g SFP Server Mainboard offers high-performance connectivity, making it ideal for modern automation systems. It features an H610/H670/Q670 chipset and supports Intel 12th and 13th generation CPUs, accommodating up to 64GB of DDR4 RAM. This board is equipped with six Intel 2.5G network card chips and optional SFP 10G ports, providing robust networking capabilities necessary for data-intensive tasks.

For smaller applications, the Piesia Nano PC Mainboard Dual Lan is perfect, thanks to its Intel Alder Lake-U/-P processors and support for up to 64GB DDR5 memory. It's designed for diverse connectivity with single or dual Intel 2.5G network options and numerous display ports, ensuring efficient operation in compact spaces.

Lastly, the Intel 11th Tiger Lake-U Industrial Firewall Nano Motherboard features a powerful blend of performance and security. It supports Intel 12th/13th generation processors with options for up to 64GB DDR5 RAM and is outfitted with diverse connectivity including LAN ports, multiple COM ports, and a range of USB options, providing both speed and reliability for industrial automation.

Key Considerations When Choosing an Industrial Motherboard

Selecting the right form factor for an industrial motherboard is crucial for optimizing space and performance in specific applications. Industrial environments often present challenges such as space constraints, requiring compact motherboard solutions like micro-ATX or mini-ITX forms. Micro-ATX boards are favored for their balance of performance and expansion capabilities, suitable for applications like Edge AI and machine vision. Mini-ITX boards, known for their small size and efficiency, are ideal for embedded applications with limited space.

When assessing performance specifications, it is essential to examine metrics such as processor speed, RAM capacity, and I/O options tailored to the application's demands. High processing power, supported by robust RAM and efficient data transfer through I/O ports, is a priority for complex industrial tasks. For instance, in environments that necessitate real-time data processing or continuous operation under harsh conditions, a motherboard with high processor performance and durable components is indispensable. Understanding the requirements of the specific industrial environment is pivotal to making an informed choice.

Future Trends in Industrial Motherboards for Automation Systems

Emerging technologies in industrial motherboards are setting the stage for transformative changes in automation systems. Key among these innovations are AI capabilities and IoT integration, which are increasingly being embedded into industrial motherboards. These advancements allow for real-time data processing and smart decision-making, driving substantial improvements in operational efficiency. As industrial environments demand more from their systems, these technologies enable predictive maintenance and adaptive responses to fluctuating conditions, reducing downtime and enhancing productivity.

The integration of AI and IoT into industrial motherboards holds the promise of revolutionizing automation. For example, AI-enabled motherboards can process complex algorithms to optimize manufacturing processes, while IoT connectivity ensures seamless communication between different industrial devices. These advancements not only streamline production lines but also facilitate sophisticated data analytics, which can offer insights into operational enhancements. Case studies have demonstrated significant gains in sectors like manufacturing and logistics, where companies employing these technologies reported enhanced system responsiveness and reduced operational costs. As these trends continue to evolve, the potential for increased automation efficiency becomes even more apparent, marking a significant step forward in industrial applications.

Recommended Products

Hot News

-

What are the benefits of using an embedded motherboard?

2024-01-30

-

Three main characteristics of industrial mainframe

2024-01-30

-

ODM/OEM service

2024-01-18

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN