PIESIA は、国内有数のハイテク企業であり、産業用制御マザーボード、完成機械、コンピューター、および関連製品の研究、開発、製造、販売、アフターサービスに専念しています。当社は、業界における専門知識により、サーバー マザーボードに関して信頼できる名前になることができました。

PIESIA では、信頼性の高いサーバー マザーボードが、あらゆるサーバー システムのスムーズな運用に不可欠であることを理解しています。そのため、当社は、お客様の多様なニーズを満たすように設計された幅広いサーバー マザーボードを提供しています。当社のサーバー マザーボードは、高品質のコンポーネントで構築されており、信頼性と耐久性を確保するために厳格にテストされています。また、お客様の特定の要件を満たすカスタマイズされたソリューションも提供しています。

PIESIA は、産業用制御マザーボード、完成機械、コンピューター、および関連製品の研究、開発、製造、販売、アフターサービスに特化した国家ハイテク企業です。サーバー マザーボードの分野では、PIESIA は品質と信頼性へのこだわりで際立っています。PIESIA がサーバー マザーボードの定番ブランドである理由を詳しく見てみましょう。

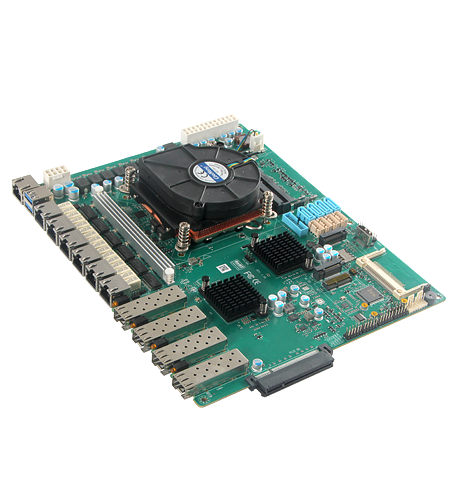

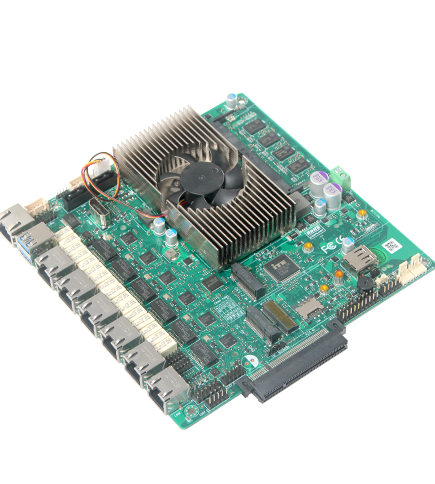

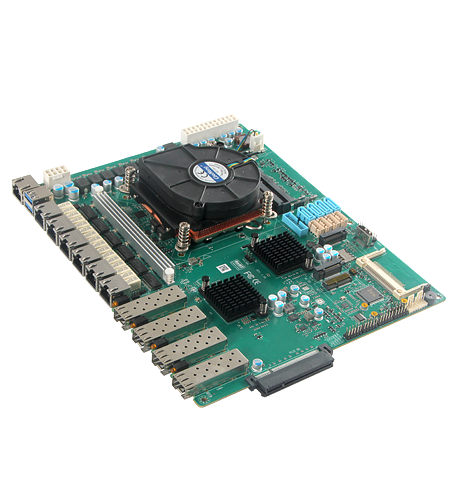

サーバー マザーボードに関しては、PIESIA は産業環境向けにカスタマイズされた高性能で耐久性のあるソリューションを幅広く提供しています。最先端のテクノロジーと厳格な品質管理を備えた当社のサーバー マザーボードは、ミッション クリティカルなアプリケーションに必要な安定性とパワーを提供します。データ センター、自動化システム、監視ネットワークなど、PIESIA サーバー マザーボードはシームレスな操作と最適なパフォーマンスを保証します。

PIESIAは,著名な国家ハイテク企業で,産業制御アプリケーションに特化したサーバーマザーボードの研究,開発,製造,販売,および包括的な販売後のサービスに特化した. 品質とイノベーションへの我々の堅固なコミットメントは, 堅牢で信頼性の高いマザーボードソリューションを提供するメーカーの中で, 私たちを最前線に位置づけています. 要求の高い環境で最適なパフォーマンスを 提供し 最も複雑な産業プロセスに不可欠な耐久性と安定性を保証します

PIESIAでは サーバーのマザーボードを 最先端技術と厳格なコンプライアンス基準で 製造するのが 核心です 自動化システムやデータ収集 重要任務の処理などで 製品が信頼性と柔軟性を向上させています マザーボードは精度と拡張性をもって構築され ライフサイクルを通して最高効率を維持しながら 無数の産業環境にシームレスな統合が可能になります 業界で深い専門知識を持つ 研究開発チームによって サポートされ サーバーのマザーボードが 今日のニーズだけでなく 未来に備えられるように 設計されています

産業用コンピューティングの分野では、サーバーのマザーボードが信頼性と効率性を確保する上で重要な役割を果たします。全国的に有名なハイテク企業である PIESIA は、これらの重要なコンポーネントの研究、開発、製造、アフターサービスに特化しています。当社は産業用マザーボード、完全なシステム、および関連技術に重点を置いており、市場で際立っています。

PIESIA のサーバー マザーボードは、産業用アプリケーションの独自の要求を満たすように設計されています。堅牢なコンポーネントと高度なテクノロジを使用して構築されており、安定性、拡張性、耐久性を確保しています。データ センター、製造工場、その他の産業環境のいずれであっても、当社のマザーボードは効率的で安全なコンピューティングの基盤を提供します。

PIESIAは、産業制御マザーボード、完全システム、コンピュータ、および関連製品の研究、開発、製造、販売、アフターサービスに注力する、国内の先進的なハイテク企業として知られています。この記事では、サーバーマザーボードの世界に深く入り込み、PIESIAがこの分野でどのように際立っているかを強調します。

サーバーマザーボードに関して言えば、PIESIAは信頼性と最先端技術を保証するブランドです。当社のサーバーマザーボードは、産業環境の厳しい要求を満たすように設計されており、最も困難な条件下でもシームレスな運用を確保します。卓越性へのコミットメントを持つPIESIAは、最新の革新と厳格な品質管理手法を取り入れ、優れた性能、安定性、耐久性を提供するサーバーマザーボードを提供します。産業用サーバーのニーズにはPIESIAを信頼し、当社のブランドがもたらす違いを体験してください。

深セン尊思智能技術有限公司 2009年に設立された同社は、工業用コントロールマザーボード、完成機器、コンピュータおよび関連製品の研究開発、製造、販売、アフターサービスに焦点を当てた国家ハイテク企業であり、 14年以上の経験 業界において。

お客様に ワンストップのカスタマイズサービス 私たちの製品は、産業自動化、通信機器、電力システム、ネットワークセキュリティ、スマート交通、ビデオ監視、医療、防衛、航空宇宙、セルフサービス端末、ストレージデバイス、デジタルサイネージ、組み込みコンピュータ、消費者電子機器など、幅広い分野で使用されています。

10年以上の業界経験、23カ国への輸出実績。

ワンストップ製品サービス、より高品質な製品を提供します。

あなたに適切な製品ソリューションを提供するために。

業界をリードするコア技術、細部へのこだわり、厳格な品質管理。

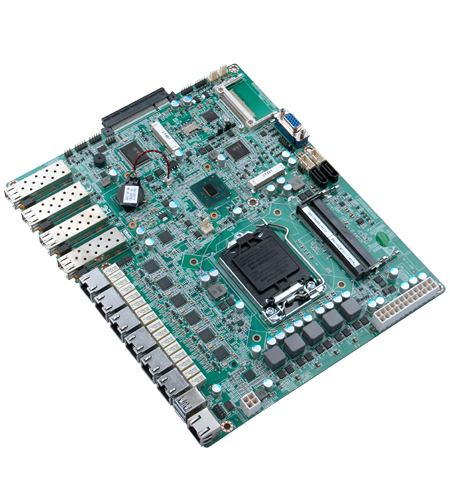

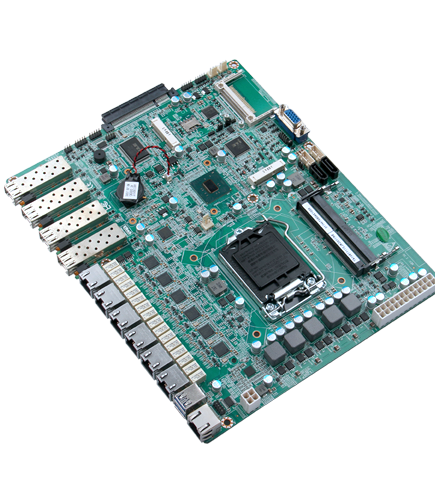

サーバー マザーボードは、サーバーや高性能コンピューティング システムで使用するために設計された特殊なマザーボードです。複数の CPU ソケット、大容量のメモリ、広範な I/O 接続など、サーバー アプリケーションに最適化された機能を提供します。

サーバー マザーボードを使用する利点には、複数の CPU のサポート、メモリ容量の増加、信頼性と安定性の機能の強化、および広範な I/O 機能などがあります。これらの機能により、サーバーは要求の厳しいワークロードを処理し、スケーラビリティを提供し、効率的なデータ処理を保証できます。

サーバー マザーボードは技術的にはゲームをサポートできますが、ゲーム用に最適化されていません。ゲーム用マザーボードは、オーバークロック機能や高度なグラフィック サポートなど、ゲームに特化した機能を備えていることがよくあります。最高のゲーム体験を得るには、ゲーム用に特別に設計されたマザーボードを使用することをお勧めします。

サーバー マザーボードには通常、ネットワーク カード、ストレージ コントローラー、その他の拡張カードを追加するための PCIe (Peripheral Component Interconnect Express) スロットなどのさまざまな拡張スロットが用意されています。拡張スロットの具体的な数と種類は、マザーボード モデルによって異なります。