PIESIA, ett ledande nationellt högteknologiskt företag, är dedikerat till forskning, utveckling, tillverkning, försäljning och eftermarknadsservice av moderkort för industriell kontroll, kompletta maskiner, datorer och relaterade produkter. Vår expertis inom branschen har gjort det möjligt för oss att bli ett pålitligt namn när det kommer till servermoderkort.

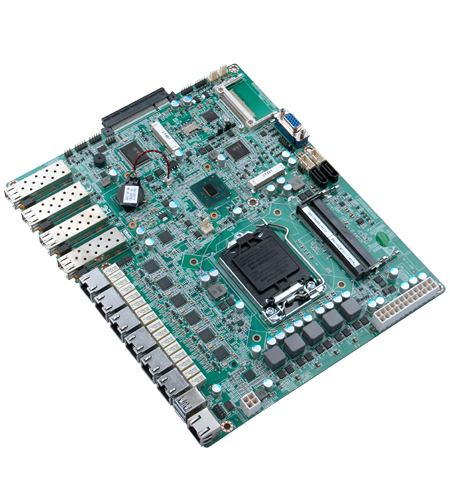

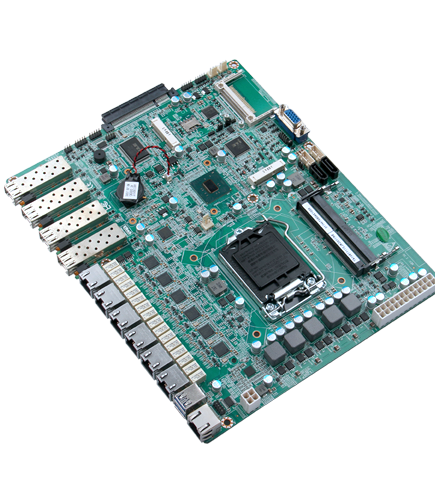

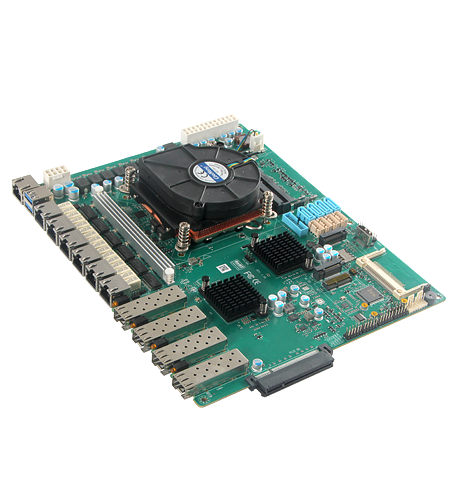

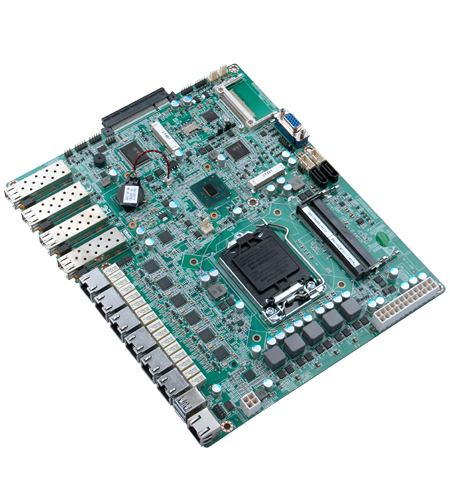

På PIESIA förstår vi att ett pålitligt servermoderkort är avgörande för att alla serversystem ska fungera smidigt. Det är därför vi erbjuder ett brett utbud av servermoderkort som är designade för att möta våra kunders olika behov. Våra servermoderkort är byggda med komponenter av hög kvalitet och är noggrant testade för att säkerställa deras tillförlitlighet och hållbarhet. Vi tillhandahåller även skräddarsydda lösningar för att tillgodose våra kunders specifika krav.

I dagens värld av snabba tekniska framsteg är ett pålitligt servermoderkort ett absolut måste för företag som förlitar sig på sina datorsystem för att utföra sin verksamhet utan problem. PIESIA, ett ledande nationellt högteknologiskt företag, specialiserar sig på forskning och utveckling (FoU), tillverkning och försäljning av industriella styrkort, hela maskiner, datorer och kringutrustning. Vår betoning på kvalitet och framsteg har gjort oss till ett branschkändt namn.

Med tanke på kraven från modern datoranvändning är vi på PIESIA medvetna om att det är viktigt att ha ett servermoderkort som kan hantera denna efterfrågan. Det är därför som våra servermoderkort är designade med banbrytande teknologi och avancerade funktioner för att garantera förstklassig prestanda och pålitlighet. Förvänta dig förbättrad systemstabilitet, ökad säkerhet, samt förhöjd energieffektivitet när du väljer att använda PIESIA-servermoderkort. Utöver det kan våra moderkort enkelt fungera med olika processorer och minnesmoduler, vilket gör dem verkligt mångsidiga enligt specifika affärskrav.

PIESIA är specialiserat på högpresterande servermoderkort för industriella miljöer. Med vårt engagemang för att utveckla och förbättra våra produkter blev vi den bästa tillverkaren av datorlösningar. Därför är PIESIA ett idealiskt märke av hårdvara som är avsedda att fungera effektivt under svåra förhållanden.

Servermoderkort som är tillverkade av PIESIA är solida och energibesparande också. I dagens oförutsägbara värld är det avgörande att skapa anpassningsbar teknik som kan stödja flera processorer och konfigurationer, vilket vi gör genom våra produkter. Varje moderkort är noggrant byggt med noggranna FoU-aktiviteter av PIESIA-ingenjörer som ser till att produkten passar varje business-to-business partners exklusiva krav.

Servermoderkort är avgörande för att säkerställa pålitlig och effektiv prestanda inom området industriell datoranvändning. Dessa vitala delar är skapade av PIESIA, ett framstående nationellt högteknologiskt företag som specialiserat sig på deras forskning, design, produktion och tillhandahållande av kundservice till sina kunder över hela landet. Vår differentiering inom marknaden ligger i att koncentrera oss på sådana aktiviteter som industriella moderkort, kompletta system samt relaterade teknologier.

PIESIA har designat servermoderkort för att möta de unika kraven för industriell användning. De är tillverkade med robusta komponenter och sofistikerad teknik som syftar till att garantera stabilitet, skalbarhet och livslängd. Oavsett om det är för ett datacenter eller någon annan plats där tillverkning sker möjliggör våra moderkort säkra och effektiva datorprocesser.

PIESIA är ett välkänt nationellt högteknologiskt företag som specialiserar sig på forskning, utveckling, tillverkning, försäljning och eftermarknadsservice av industriella styrmoderkort, kompletta system, datorer och andra relaterade produkter. I den här artikeln kommer vi att utforska domänen för servermoderkort och visa varför PIESIA utmärker sig på detta område.

När det kommer till servermoderkort kan du alltid räkna med att PIESIA är pålitlig och använder den senaste tekniken. Våra servermoderkort är tillgodosedda med sådan noggrannhet att de kan fungera felfritt även under de svåraste förhållanden. Detta resulterar i ett orubbligt engagemang för den senaste utvecklingen samt snäva kvalitetskontroller för att producera servermoderkort vars utförande, stabilitet och livslängd är oöverträffad. För dina industriella servrar behöver lita på PIESIA och känna vår varumärkesskillnad.

Shenzhen ZunSia Intelligent Technology Co., Ltd. Företaget grundades 2009 och är ett nationellt högteknologiskt företag fokuserat på forskning, utveckling, tillverkning, försäljning och eftermarknadsservice av moderkort för industriell kontroll, kompletta maskiner, datorer och relaterade produkter, med 14+ års erfarenhet inom branschen.

Vi förser kunder med En-stop Anpassade tjänster , Våra produkter hittar omfattande tillämpningar inom industriell automation, kommunikationsutrustning, kraftsystem, nätverkssäkerhet, intelligent transport, videoövervakning, sjukvård, försvar, flyg, självbetjäningsterminaler, lagringsenheter, digital skyltning, inbyggda datorer, hemelektronik och mer .

Mer än 10 års branscherfarenhet, export till 23 länder.

Produkt one-stop service, för att förse dig med produkter av högre kvalitet.

För att förse dig med lämpliga produktlösningar.

Branschledande kärnteknologi, uppmärksamhet på detaljer, strikt kvalitetskontroll.

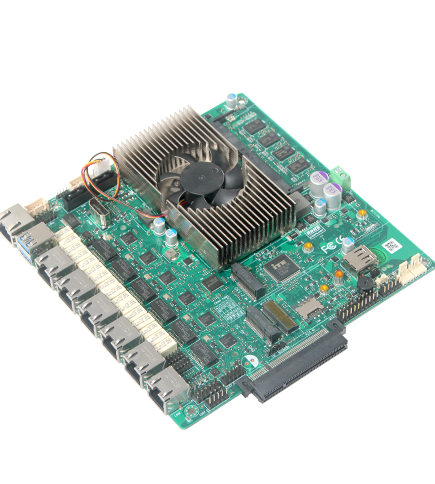

Ett servermoderkort är ett specialiserat moderkort designat för att användas i servrar eller högpresterande datorsystem. Den tillhandahåller funktioner och möjligheter optimerade för serverapplikationer, såsom flera CPU-sockets, stor minneskapacitet och omfattande I/O-anslutning.

Fördelarna med att använda ett servermoderkort inkluderar stöd för flera processorer, högre minneskapacitet, förbättrad tillförlitlighet och stabilitetsfunktioner och omfattande I/O-möjligheter. Dessa funktioner gör det möjligt för servrar att hantera krävande arbetsbelastningar, ger skalbarhet och säkerställer effektiv databehandling.

Servermoderkort kan tekniskt stödja spel, men de är inte optimerade för det. Gaming-moderkort ger ofta funktioner som är specifika för spel, såsom överklockningsmöjligheter och avancerat grafikstöd. Det rekommenderas att använda ett moderkort speciellt designat för spel för bästa spelupplevelse.

Servermoderkort tillhandahåller vanligtvis en mängd olika expansionskortplatser, såsom PCIe-platser (Peripheral Component Interconnect Express), för att lägga till ytterligare nätverkskort, lagringskontroller eller andra expansionskort. Det specifika antalet och typen av expansionsplatser kan variera beroende på moderkortsmodell.